BEHLEN New Robotics – Press Release

April 29th, 2015

The Industrial Revolution transformed how we do work and paved the way to large scale production. Through mankind’s constant desire to innovate and reach new heights we have seen a new revolution transform before our eyes. The technological revolution has shown us that even the unimaginable is possible!

At BEHLEN Industries, Canada’s largest manufacturer of steel building solutions, they are reaffirming this notion of making the impossible possible, with a new one-of-a kind technology.

Until now, robotics in welding has been traditionally used for predefined, repetitive tasks with little to no variability. At BEHLEN, their in house engineers and detailers realized that it was necessary to be able to gain the benefits of robotics and advanced software in welding, without having any limitations.

“We have such talented engineers, detailers and production staff in house at BEHLEN that we are not only capable of taking on many new challenges, but enjoy doing so.” says Sean Lepper, Vice President & General Manager.

Every project at BEHLEN is custom, so robotic technology had only a small place in their plant, for the few repetitive processes that they do, almost everything else was done manually. There are many benefits to an automated process in steel manufacturing like increased product quality & capacity; decreased errors at every level of the business & in the product itself; and increased communication with clients.

While robots in manufacturing are not a new technology, it is BEHLEN’s strategically chosen and innovative combination of software, robotics and processes that has allowed them to successfully implement the use of robotic technology for custom manufacturing.

“Robotic welding is typically a high volume, low variable type of process, but at BEHLEN, we needed the opposite. Since almost all of our production is custom-designed, we needed to find a way to make our robotic welding cell be used for high variable, low volume work.” says Pat Versavel, Vice President – Engineering and Innovation.

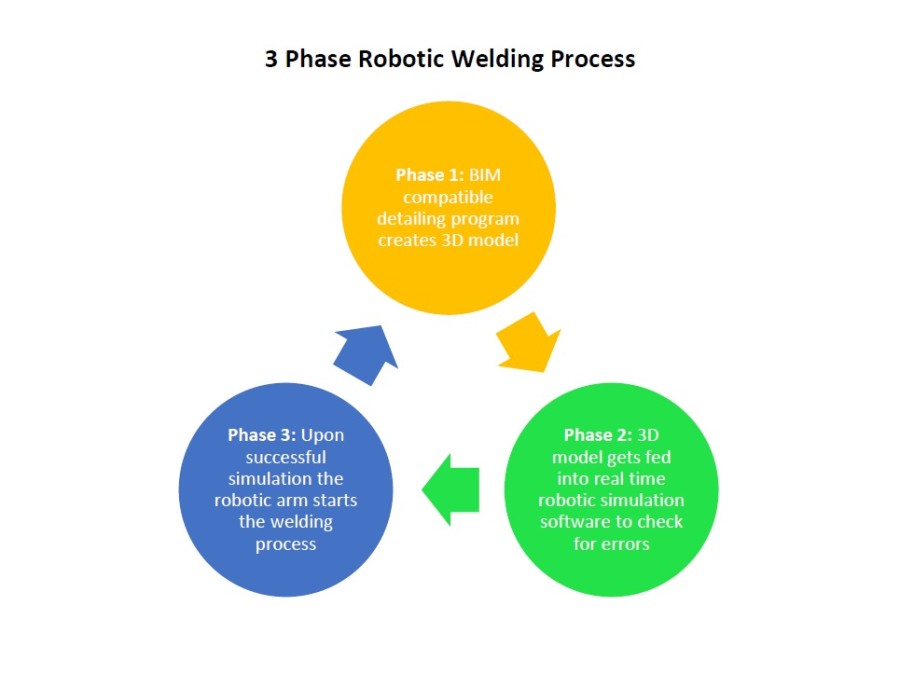

The 3 step process starts with a detailing program rarely used in the pre-engineered steel building sector, BEHLEN engineers are able to create a hyper-detailed and organized 3D model, including specs of each individual part of a project. That model, which can also easily be shared and used by clients and imported into BIM systems, is then fed into a second piece of software.

The second phase, a robotic simulation program uses touch-sensing with the robotic arm to detect any potential errors or clashes and then produces a real time, visual simulation of the weld. This is the first time this software has been applied to welding, a process that was more than one-year in the making.

Phase 3 is when the robot welding arm goes to work. Using a metal-cored arc welding technique, the robot is able to make any kind of weld imaginable. The robotic arm is connected by a power source that was strategically chosen to create the fastest possible machine of its kind, to date.

Through the new technological welding process BEHLEN has been able to increase their plant productivity in a key area. As BEHLEN continues to take on more and bigger projects, the new robotic welding technology is just the start, they already have plans to add more identical robots to further increase plant capacity.

BEHLEN is the first pre-engineered steel building manufacturing plant in North America, and possibly the entire world, to employ this new technology in such an effective combination.

Over the past 40 years, BEHLEN Industries LP has grown to be the largest manufacturer of steel building systems in Canada. It now serves customers worldwide through a growing network of authorized builders and continues to earn a reputation as a global leader.

Rosa Villamizar

Marketing Manager

BEHLEN Industries LP

p. (204) 578-3739

e. rvillamizar@behlen.ca

Written by:

BEHLEN Industries LP