The Importance of Sealants When Installing Insulated Metal Panels

Insulated Metal Panels or IMPs, are premium building components that provide superior thermal and building envelope performance for both roof and walls. Known for their high R-value and low U-values, IMPs are the smart choice to meet the changes to NEBC 2020 across all Climatic Zones.

A key component in a successful IMP installation is the proper placement of sealants. Location, placement and continuity must be looked at carefully during the design, detailing and installation.

Sealants are an important part of the air vapour barrier for air leakage rates prescribed by the NBCC to ensure proper building envelope performance. IMP side joints are a modified tongue and groove assembly that must be filled with continuous, uninterrupted butyl tube sealant. This continuous and uninterrupted sealant includes sealing all perimeters and openings using sheet steel, gun-grade butyl tube and tape applied butyl sealants. This continuous perimeter sealant barrier is required between the panels and the structure, interior to exterior flashing assemblies, and within the panel joints. Placement of field applied sealants is of utmost importance to prevent air movement. Even the smallest of gaps interrupting the continuous run can allow air to move from inside of a building; air can migrate into the joints, panel end laps or around opening. It will condense on the colder side of the panels creating moisture that will accumulate on the interior surface, gravity can pool it onto other surfaces or create drips from the ceiling. Problems can occur through the freeze thaw cycling from night to day, creating openings at joints or other termination points, thus compounding the rate of air leakage.

Always create a plan to ensure site quality, supervision and continuous sealants on your IMP project. Watch for scopes of work or other trades that could corrupt the air vapour barrier, and address early in the construction design. Certain, complex penetrations or openings may require additional consideration for sealing that goes beyond manufacturers standard details and could require specialized AVB membranes and flashings.

Remember, the IMP doesn't leak – everything around it does, so ensure your AVB is continuous.

BEHLEN Industries LP uses ARTSPAN Insulated Metal Panels: Click here for more about our panels

BEHLEN Industries LP uses ARTSPAN Insulated Metal Panels: Click here for more about our panels

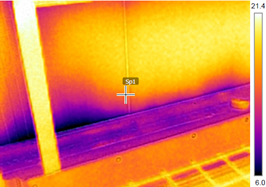

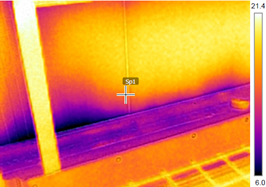

This Insulated Metal Panel (IMP) Install picture demonstrates issues doe to the lack of and broken sealant between base support angles and base trim.

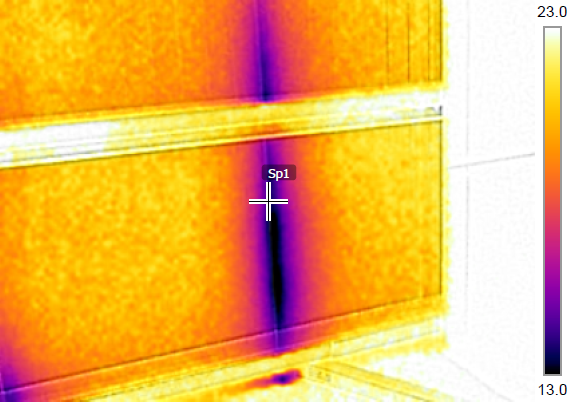

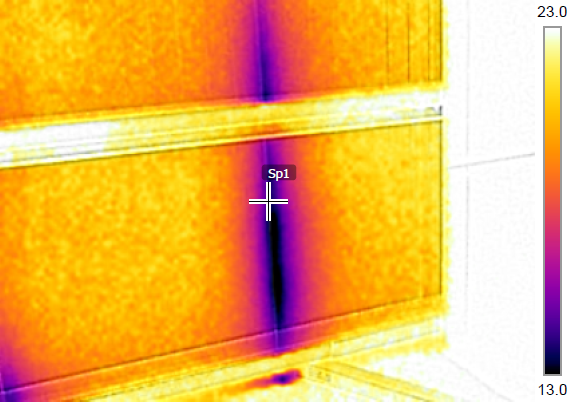

This Insulated Metal Panel (IMP) install picture demonstrates an issue which results when there is missing sealant at panel joint.

Written by:

David Forsey

Architectural Representative

BEHLEN Industries LP